Higher Accuracy In Color Matching

With our experienced dyeing experts and professional Lab equipment, Wing Yue can ensure precision color matching.

Looking for professional dyeing service? Wing Yue can submit L/D for color approval within 3 working days.

Before submitting lab dip to customer, our technicians will compare it against the color standard under professional light box, and undergone performance tests like color fastness and anti-yellowing.

All approved lab dips are stored in black plastic bag in our professional data center with related information. After received orders, technicians will build up dyeing formula for bulk before dyeing in order to keep the consistency and repeatability of all orders.

Explore Our Color Matching Labs >>With the dyeing formula set from our experienced technicians, the greige fabric could be obtained a bright, uniform, and firm colors after dyeing.

When the gray fabric is immersed in a dye aqueous solution at a certain temperature, it will interact with dyes until the dyeing has reached an equilibrium state.

After that, the greige fabric is completely dyed, and under no circumstance, the dye still stays in the fiber, maintaining a superior fastness.

Preparation of fabrics to undergo dyeing and finishing processes is critical, which is the first step of to get perfect finished products.

By scouring, we can remove various impurities on the fabrics through the chemical and physical mechanical effects, so that the qualified semi-finished fabric is soft and has good penetration properties, which helps us to improve the absorbency of fabric and ensure the uniformity of dyeing.

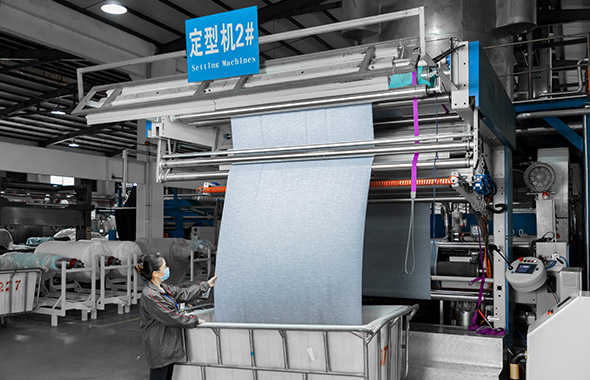

According to the process requirement, our staff will give the greige fabrics a stable property by thermo fixing to avoid color change in dyeing.

To remove natural impurities, slurry, oil stains on the fabric, ensuring it with soft feel, good water absorption rate, which make it to be qualified semi-finished products.

With 20 sets of dyeing machines with capacity from 25kg to 1500kg, we can achieve your requirement on the color of your order.

After dyeing, the fabrics contain a lot of water, so it is necessary to squeeze out the water to save the time and energy consumption of drying process.

By spraying hot air onto the fabric, the drying machine can achieve no contact drying, which can maintain the fluffy and rich feel of the fabric.

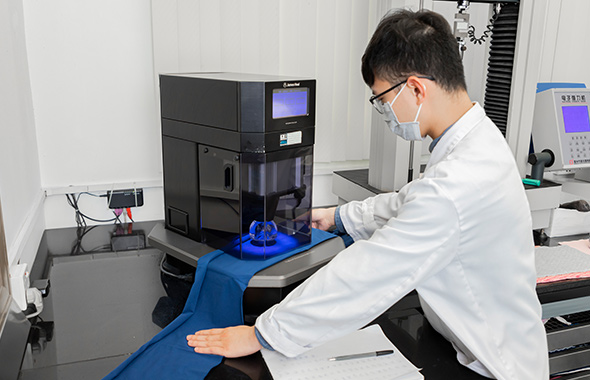

After drying, we will arrange the semi-finished fabric to conduct all color fastness tests and check the color, pattern, sizes and quality.

When the fabric is after setting process, their physical specification such as shrinkage, fabric width and weight are relatively stable and the fabric surface is relatively flat. At the same time, fabric functional such as waterproof, softness, resin, flame retardant, antistatic, wicking, antibacterial and deodorant, can be added.

The finishing after dyeing allow us to give the fabric with functional features and improve its physical performance.

For synthetic fabric, it should be “oil-removed” before dyeing ; For cotton fabric, it is necessary to be “pre-shrunk” to improve its shrinkage. Anyway, fabric can be “waterproof” by covering a chemical coating on it’s surface.

Our dyeing experts with over 20 years of experience will pay close attention on the whole dyeing process.

Sample will be randomly picked to check with it’s dyeing performance by color comparison during any stage in dyeing process. The fabric will be folded to check the dyeing uniformity of the left, middle and right sides of it.

We will base on customer’s testing requirement to conduct fabric testing at certain stage in production to ensure our the fabric performance could be achieved customer’s requirement

Before shipment, we will draw 2 meter sample to conduct fabric test based on customer’s requirement.

With our experienced dyeing experts and professional Lab equipment, Wing Yue can ensure precision color matching.

We offer a full range of dyeing & finishing services for a wide range of fabrications. With using the dyeing stuff fulfilling Oeko-Tex Standard 100 & RSL, advanced machines and skillful workers, we guarantee to provide the highest quality products to you.

With high-performance dyeing machines from Asia Kingdom, Brazzoli and Fong's, Wing Yue proceeded thousands of tons of fabric every year. The capacity of dyeing machines are from 25kg to 1500kg.

Besides our excellent dyeing service, we can also apply a range of functional finishing and printing to enhance our products’ properties and performances. At Wing Yue, you can really get one-stop solution.

Copyright© 2022 Wing Yue. All Rights Reserved.