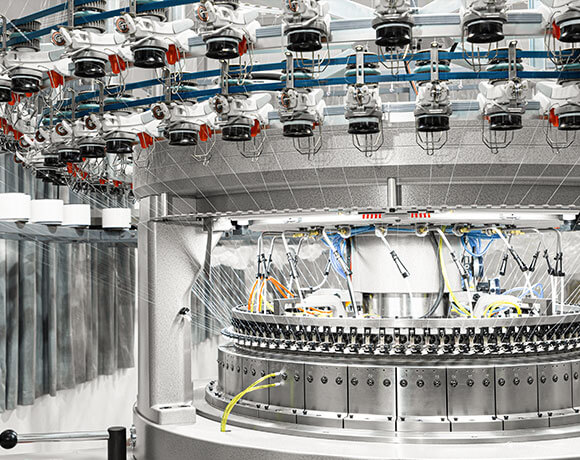

We will conduct various tests to ensure the quality of yarn materials according to specific standards.

For all yarns, we will test yarn twist, linear density, and strength with professional machines, and weed out yarns of stain, uneven line, impurities for all of our yarn via careful inspection.

For dyed-yarns, we will add one more color fastness test to guarantee its performance in subsequent productions.